Graycer Machinery List

Inventory subject to change without notice.

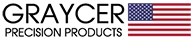

Turning Machinery

4 Tsugami M08SY-II Turning Centers with Y axis 8″ chucking and 2 1/2″ bar capacity. Cross milling and drilling, sub spindle for back working. Click Here

7 Star SR-20R111 CNC Swiss Automatic Turning Centers IEMCA Magazine Bar Feeder, Cross drilling, Milling, Indexing . Simultaneous Back Working and 6 Axis machining for the more complicated parts. For more information on these machines, click here

5 Star CNC SB-20 CNC Swiss Automatic Turning Centers IEMCA Magazine Bar Feeder 11/16 capacity, cross milling and drilling, sub spindle for Simultaneous Back Working. For more information on these machines, click here.

3 Star SR-32J CNC Swiss automatic turning center IEMCA magazine bar feeder 1 ¼” capacity. cross milling and drilling. sub spindle for simultaneous back working. For more information on these machines, click here.

5 Star RNC – 16B CNC Swiss Automatic turning centers with IEMCA magazine bar feeders and back working spindles, 5/8″ dia. capacity.

1 Star SST – 16 CNC Swiss Automatic EMCA magazine bar feeder, cross milling, drilling units, pick off spindle, 5/8″ dia. and 12″ length capacity.

1 Star SR-20 CNC Swiss Automatic IEMCA magazine bar feeder, 11/16” capacity, cross milling and drilling, sub spindle for simultaneous back working.

1 Hardinge GS-51 CNC lathe with 8″ chucking and 2″ bar capacity.

1 Hardinge GS-200/66 CNC lathe with 10″ chucking and 2 5/8” bar capacity.

1 Hardinge Talent CNC lathe with 10″ chucking and 2″ bar capacity. For more information, click here

1 HAAS TL-2 toolroom/CNC production lathe, 10” chuck, 3” spindle bore. For more information on this machine click here.

Milling Machinery

3 Matsuura RA-IF vertical milling centers, Yasnac 180M control with dual pallets, 16″ x 20″ travel

1 HAAS Mini Mill, Haas control with 4th axis, 16″ X 12″ travel

1 HAAS VF-3 Haas control with 4th axis, 20″ X 40″ travel

2 HAAS VF-2SS 12,000 RPM spindle, Haas control with 4th axis, Renishaw probe, 20″ X 30″ travel

1 Fanuc Robodrill a-D21mib5 with 21 tools Fanuc control with Renishaw Probe.

1 Bridgeport V480 APC duel pallet 30 tool milling machine. Click here

Support Machinery

4 Hardinge retrofit CNC gang style chucking machines with Fagor controls

4 Hardinge DSM59 lathes

2 Hardinge type super precision lathe.

2 engine lathes, 15″ swing

6 Bridgeport milling machine

1 Clausing six-spindle drill

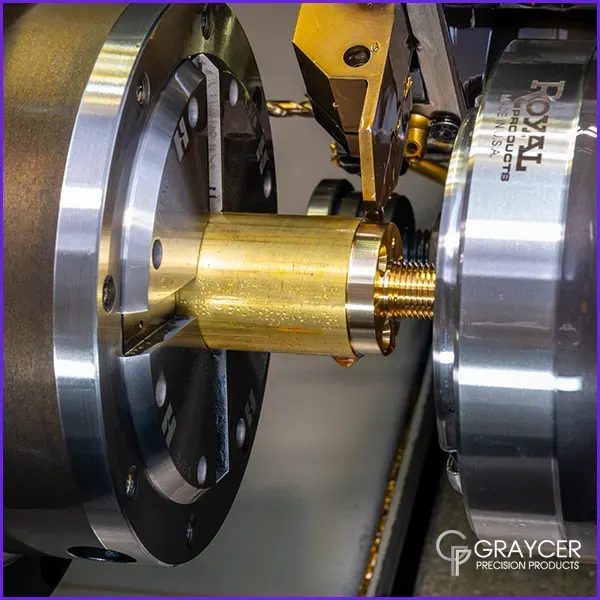

2 Cosin automatic cutoff saws. 12” Round capacity.

Inspection Equipment

1 Brown & Sharpe computer controlled CMM

1 Starrett HB400 optical comparitor with computerized reedout.

1 Gagemaster high resolution optical comparator GMX computer with digital readout, accuracy to .0001

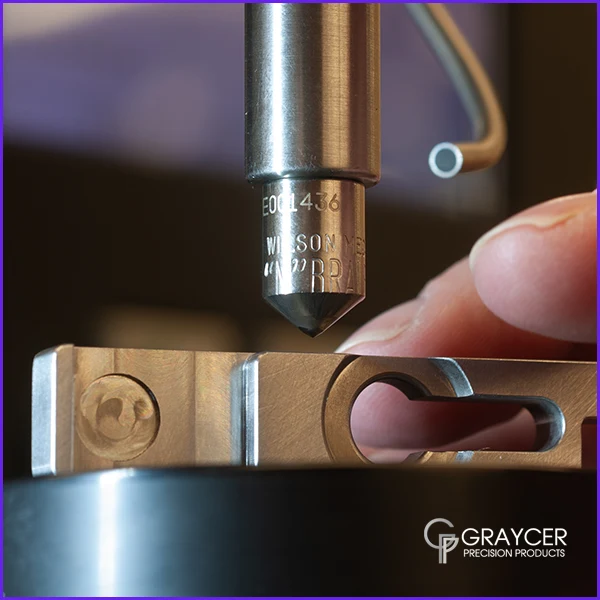

1 Rockwell 2000 series CNC hardness tester for in-house inspection of all heat treated products

1 Mitutoyo PH361 profile projector comparator with digital readout

2 master gage block sets

1 Mitutoyo surface roughness tester

2 complete sets of plug gages ranging from .010″ to .750″

Huge selection of thread ring and plug gages, all calibrated to national standards .